Higher transparency

and more security for your process

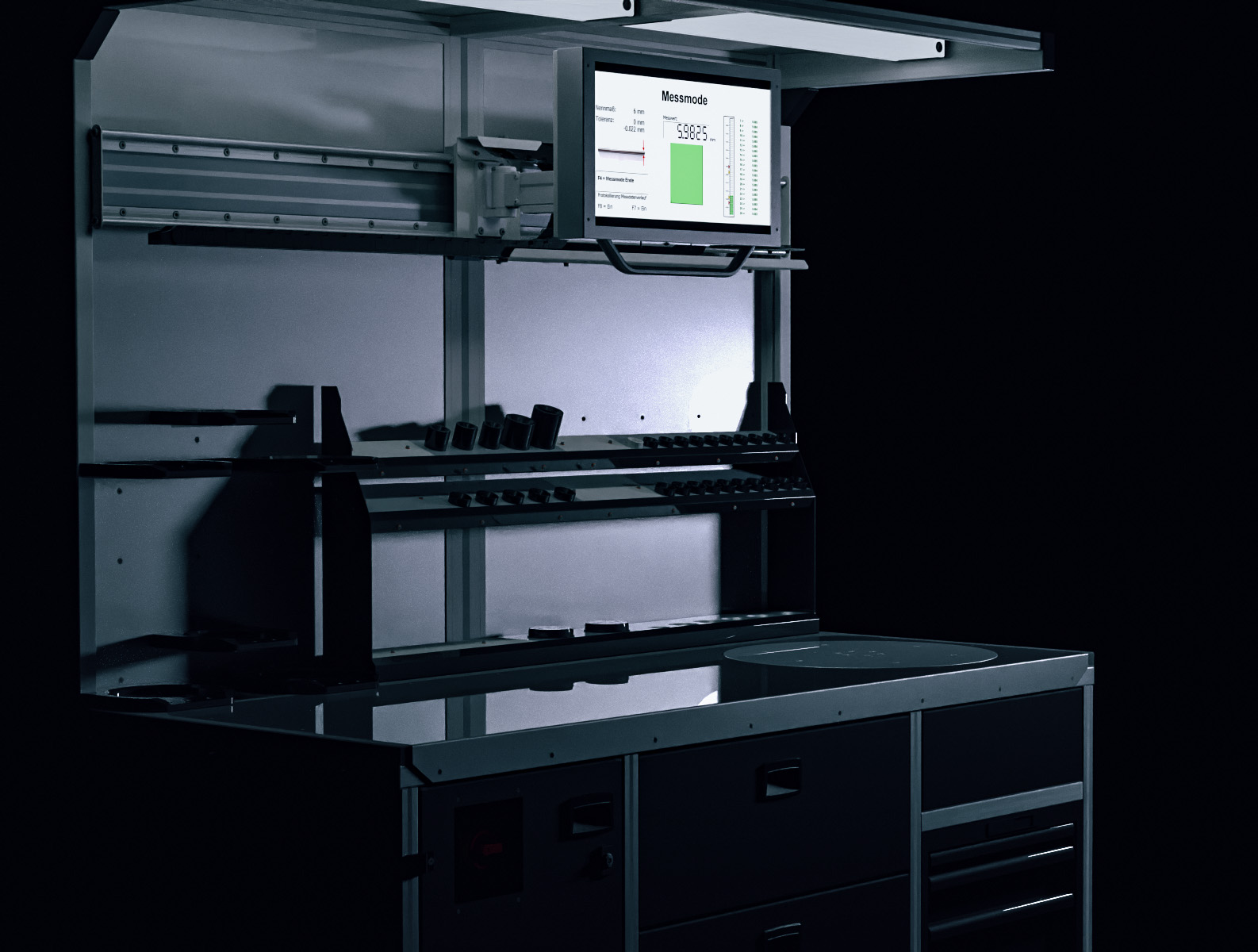

The DISIONIC TABLE is designed to support your workers in the areas of production, assembly as well as quality control. The versatility of our measuring tables & inspection tables can also be seen in the diverse industries in which the intelligent measuring workstation has already been installed. From the automotive industry to medical technology, our customers benefit from the variability of the system.

At the same time, the DISIONIC TABLE works in a standardised manner and can be integrated into CAQ systems, on a statistical level or integrated into a host computer on the machine level. In any case, you can work with our measuring tables in a time-saving and cost-optimised manner and accelerate your production process.

Der DISIONIC TABLE dient der Unterstützung Ihrer Werker in den Bereichen Fertigung, Montage sowie der Qualitätskontrolle. Die Vielseitigkeit unserer Messtische & Prüftische lässt sich auch an den diversen Branchen erkennen, in denen der intelligente Messarbeitsplatz bereits installiert wurde. Von der Automobilindustrie bis hin zur Medizintechnik profitieren unsere Kunden von der Variabilität des Systems.

Dabei arbeitet der DISIONIC TABLE standardisiert und kann in CAQ-Systeme eingebunden werden, auf statistischer Ebene oder an einen Leitrechner auf Maschinenebene integriert werden. In jeden Fall arbeiten Sie mit unseren Messtischen zeitsparend und kostenoptimiert und beschleunigen Ihren Fertigungsprozess.

Ensure more safety in the process with intelligent worker guidance. Each work step is indicated, measured values are stored and documented. The integration of control systems and peripherals minimises production errors.

Create your own work instructions and design your processes flexibly and safely. The software offers many possibilities and can be linked to higher-level QSM and SAP systems.

Always the right tool and measuring equipment for the job. No problem with the pick-to-light function. The software assigns each work utensil to a place and marks it with a matching LED.

Several suitable tools can be assigned to each process step. The individual adaptation to your needs is crucial for us.

Whether a label printer for documentation or a screwdriver control for the assembly of a component, every process requires individual tools for implementation.

Our SPC workstation systems enable the implementation and installation of versatile peripherals through customised adaptation to the requirements of our customers.

This also includes all measuring and assembly systems for process monitoring, which communicate with the integrated plant management through interfaces.

We adapt the standards of the DISIONIC TABLE exactly to your requirements. All measuring equipment and tools are integrated and stored in a location-specific manner. Your employees do not have to search for drawings, note down data in Excel lists or decide which measuring equipment to use. The intelligent SPC measuring table has a tool guide specially developed for your production, which guides your employees through the process error-free.

Tools and test equipment can be reached in the shortest possible time thanks to the pick-to-light function and the ergonomically planned deposit point. Measuring systems monitor every work step and guarantee error-free assembly. Tests are automatically confirmed and all measured values are independently documented by the measuring table.

The release of machines and hardware is also fully automated by the measuring station by calling up specifications from predefined measuring programmes and integrating the corresponding documents. The preparation and processing of possible test and characteristic values is realised independently by the software. The factory management defines the new standard of production and tells your employees exactly what to do and when.

It is the combination of these numerous features that makes the DISIONIC TABLE so efficient: optimum quality control, state-of-the-art technology and standardised worker guidance precisely adapted to your needs. Your measurement results are recorded, verified, evaluated and stored. You can rely on stable measurements, a secure process chain and absolute traceability of the data. Maximise the quality of your products with clear characteristics and values. The Table also detects faulty processes and provides reliable quality statements.

and more security for your process

We adapt the standards exactly to your production process and your component

through a shortened production time

Lead to higher throughput with your existing equipment

Thanks to automation, you minimise reworking times and faulty productions

Minimisation of error sources and reduction of the complaint rate

Reduction of rejects and special releases

Complete documentation of the testing process incl. traceability

Every process has its requirements and we tailor our SPC workstation systems to optimise yours.