Special solutions presented

Discover the diversity of our projects by means of selected examples

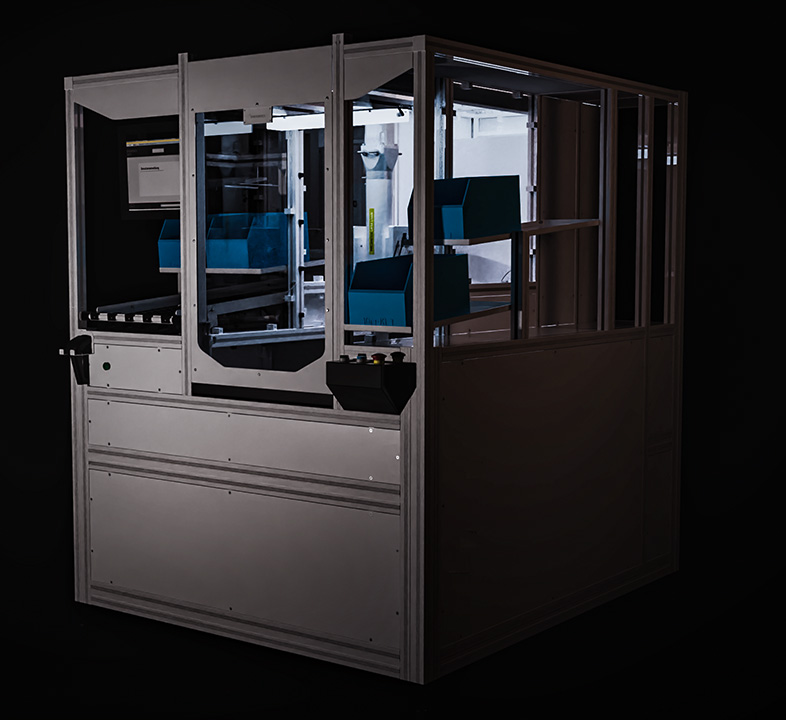

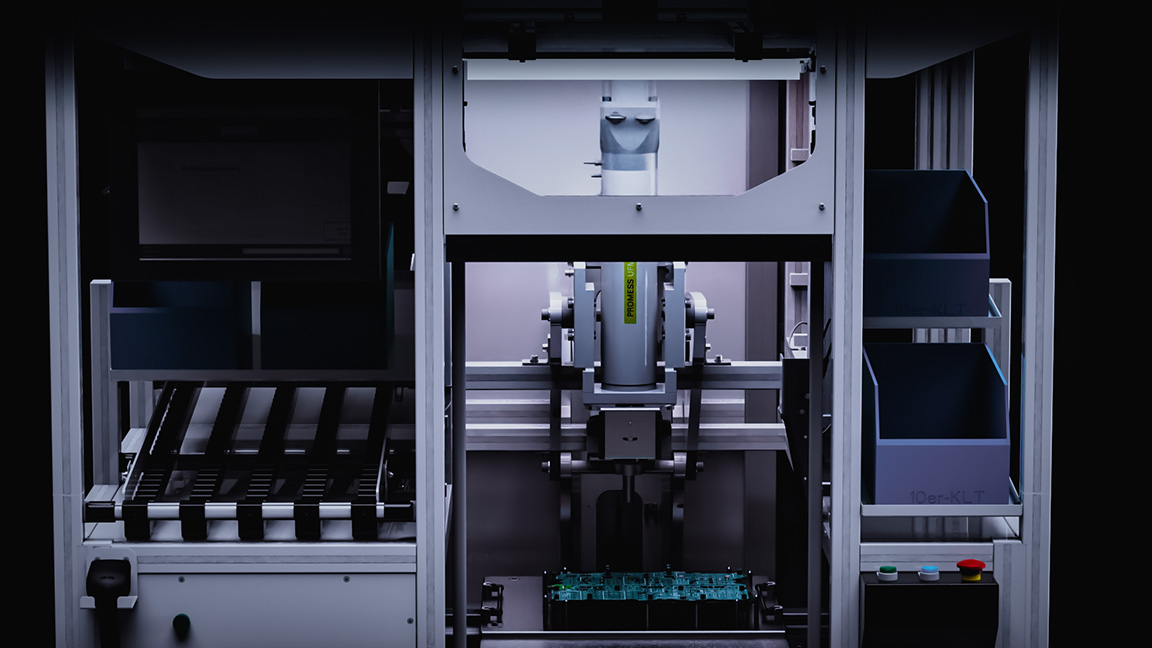

Automated PCB assembly

Fast, precise and automated pressing

Originally developed for the assembly of printed circuit boards, the system can be adapted to all manufacturing processes that require precise positioning and a defined application of force. Shearing processes, punching, primary forming are just as much a part of the task as pressing itself. The integrated cross table ensures highly accurate positioning of the workpiece, the integrated measuring technology checks the components for correctness, presence, position and alignment, thus guaranteeing a reliable process for your production.

After successful infeed, the barrel is moved to the alignment position by means of a gantry with integrated vacuum suction cup. The exact alignment of the barrel is relevant due to the presence of mirror shadows and a weld seam, as a tactile measurement is carried out on the surface.

Main focus of the projects

- Designed for fully automated production environments

- Designed for PCB assembly in power electronics

- Creation of own programme sequences for individual board designs

- Individual tools for a wide range of component types

- Monitoring of the process through integrated measurement technology (position check, component recognition, force control monitoring, etc.)

- Processing of data for quality management

You have a task and are looking for the right solution?

Contact us. We look forward to a joint exchange.