Special solutions presented

Discover the diversity of our projects by means of selected examples

Application examples

Discover our sample applications in our overview and learn the first information about the complex projects.

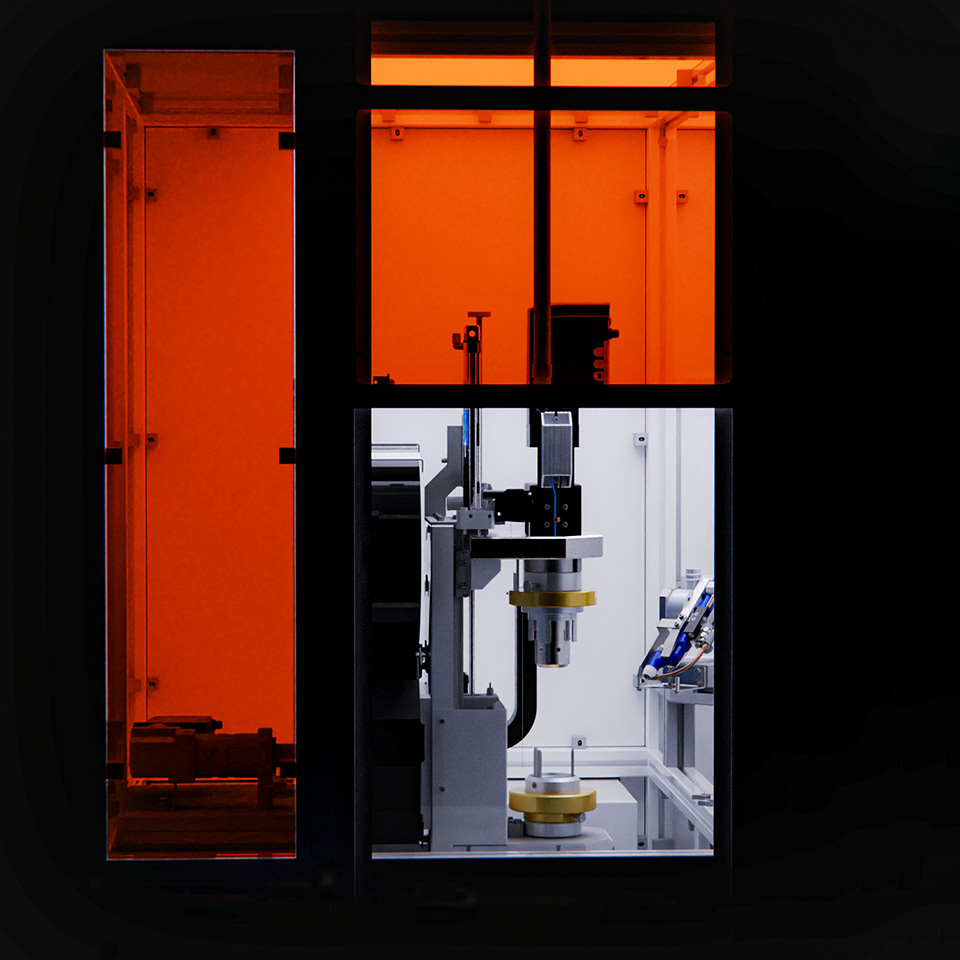

Automated barrel measurement

The demand for ever more precise manufacturing and the associated documentation of the results does not stop at one of Germany's most popular industries: beer brewing. In this case, the task was to randomly measure barrels rolled and formed from sheet metal for external characteristics. The system relied on the optimised interaction of optical and tactile measuring technology.

Automatic welding machines

Different welding processes in the automotive sector. Two separate systems that go different ways, not only in the welding process. One as a single system for production, the other as part of a production line, both systems differ in terms of their requirements, operation and complexity. We would like to present both projects to you here.

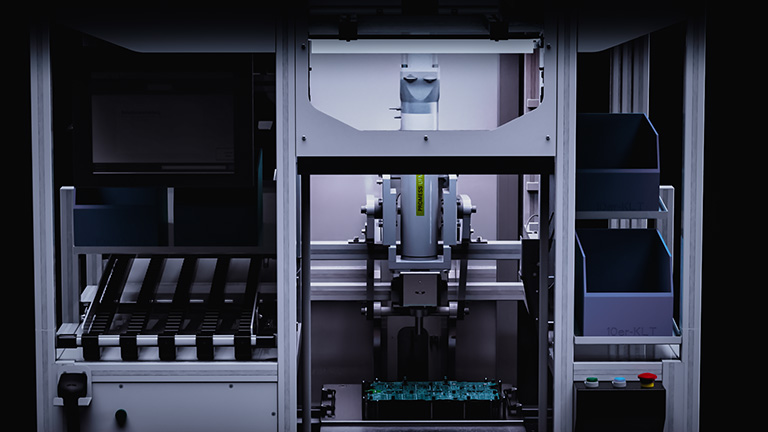

PCB assembly

The interplay of precise pressing technology and state-of-the-art inspection systems enables highly accurate assembly of a wide variety of board types. These are recognised by the system in exactly the same way as the components to be pressed in and checked for position, location and alignment.

Wiring assistant

Our goal is to create optimal working conditions for our customers and their employees. The task in this case was to optimise the process of manually wiring circuit boards. The individual boards are made by hand, with wires the thickness of a hair and soldering points barely visible to the naked eye.

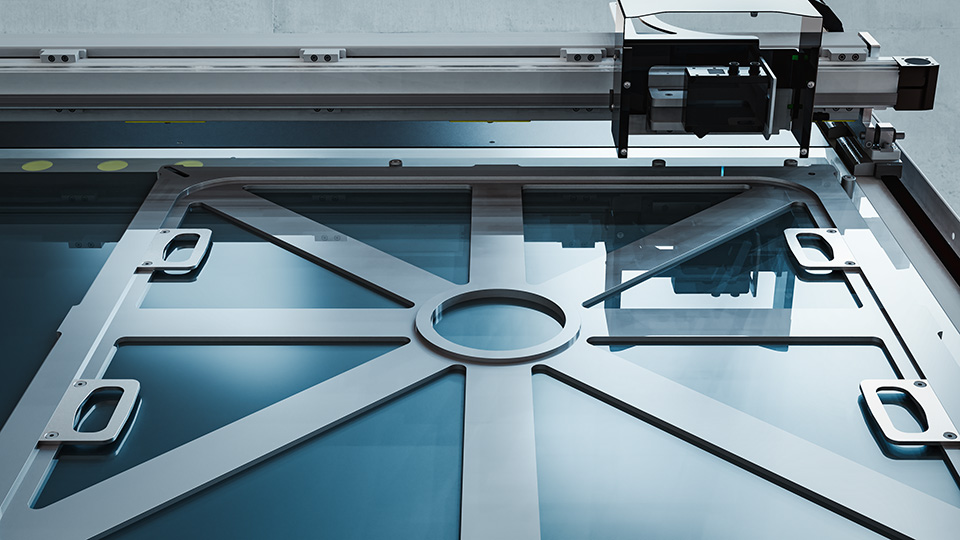

Sheet metal measurement

This coordinate measuring table for quality control is designed for high-precision inspection of sheet metal. Standard for measuring rectangular sheets with dimensions up to 1.5 x 1.5 metres, the system can be individually adapted to different requirements. Even complex contours and reflective materials can be scanned with high precision by the built-in optical sensors.

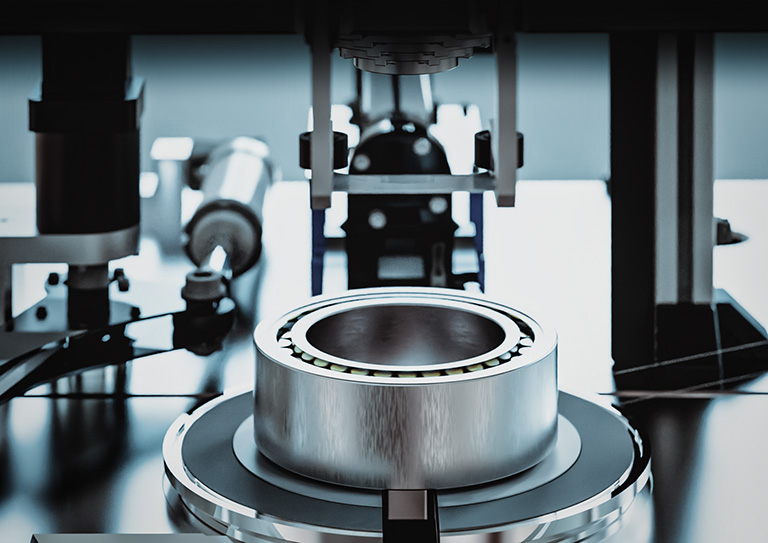

Bearing play detected tactilely

A system was developed for measuring the axial-radial bearing clearance of rolling bearings, which was included in a test track. The highly accurate testing of the play is carried out according to ISO 1132-2 section and impresses with the large variety of possible bearings, as well as fast cycle time and high precision.

You have a task and are looking for the right solution?

Contact us. We look forward to a joint exchange.